Loop of belt drawn by pulleys is what a Conveyor Idler Roller refers to. In order to handle the high level applications, the exclusive design is formed in such a way that it handles the surrounding. Apart from their ability to adjust in the toughest environment, they need high level of operational reliability.

- Need less maintenance cost

- Offer durability, strength and low-noise level

- Reduce the impulsive force to provide optimum service life to belt

- Suitable for any tension load and bending movement

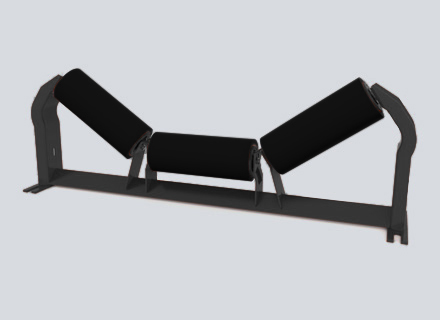

Idlers

Idlers are an important part of a conveyor system. They support the belt after it has been loaded; thus, allow it to move material from one place to another. Idlers are possible to remain in a fixed location and can also be made adjustable.

What Makes Us Different?

Logicraft has its colossal reasons that make it not just different but better than others. Apart from sincere efforts and extensive hard work, we manufacture idlers that handle higher tonnage over greater distances at lower costs per ton. Standing apart from other manufacturing industries, our idlers:

- Ensure sleek transition of bulk material for long period of time.

- Are available with impact rings that are made of shock absorbing compound.

- Are manufactured as per customer’s design and drawings, be it any angle.

- Meet world-wide standards.

- Are fitted with anti-seize bearings to elongate their life.

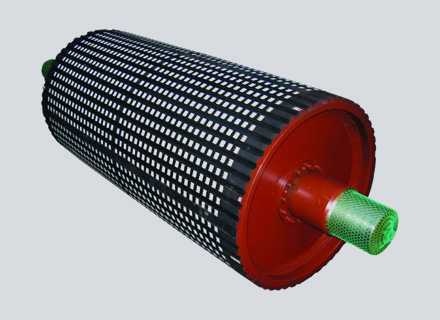

Rollers

A fundamental element of conveyor system, rollers reduce the wear & tear of the whole method and hence, extend its life. They are precision powered and come in both chain and belt-driven models.

What Makes Us Different?

We manufacture a precision engineered range of rollers, as innovation is our forte. Unlike others, we take every step keeping in mind client’s needs and hence, create rollers in a number of shapes, sizes, lengths, materials and weights with sheer focus on technical specifications. Our rollers:

- Are developed with multipass labyrinth sealing to prevent leakage.

- Are available in multiple bearing housing and sealing structure, according to client’s choice.

- Are manufactured only with concepts and inputs from customer’s end.

- Are available with a range of coverings.

- Have latest configurations and sophisticated controls to handle heavier items.

Pulleys

Used on conveyors, pulleys support and deflect the belting via the conveyor structure. They are used to transfer the drive power in the conveyor belt and are subjected to the dynamic belt tension forces in the conveyor.

What Makes Us Different?

Dealing with manufacturing of pulleys since decades, we know how important the design of the shafts is. We also understand the crucial role of pulley diameter, hubs, shells and other locking elements. With all these considerations in our work, we create pulleys that redirect, drive, provide tension to, assist in tracking the conveyor belt. Pulleys manufactured by us are:

- Available in various configurations.

- Developed in a way to guarantee fault-free operation.

- Manufactured with application of lagging to protect the guarding layer from premature failure.

- Equipped with clamping elements to prevent the welds being loaded.

- Undergo a standard inspection of clamping torques, weld seams, dimensions, bearing clearances and static & dynamic balance, as requested by the client.

Services Tailored To Your Organization

We’ve helped several organizations with a well-structured process built on best practices. Our approach includes help with every step. We have developed a long-lasting relationship with factories around the world to meet every client’s individual needs.